A generator construction is a complicated engineering process involving a variety of components. It typically involves the assembly of a frame, fuel system, electrical system, cooling system and control system. Depending on the type of generator, there may be additional components as well. The frame of a generator construction is designed to hold and protect all components, as well as absorb any vibrations during operation. The fuel system is used to convert chemical energy into mechanical energy and is usually composed of a fuel tank, fuel pump, fuel injectors and fuel lines.

The electrical system includes the alternator, starter motor, and the system’s battery. The cooling system is used to regulate temperature and includes a radiator, hoses, fan, and thermostat. The control system is responsible for managing and monitoring the generator’s performance. Generator construction also requires precision measurements to ensure proper alignment and installation of components. The components are then joined together using a variety of methods such as welding, soldering, or riveting. Once the generator is assembled, it is tested and calibrated to ensure it operates efficiently and safely. Generator construction can be a complex process and requires a wide range of skill sets. It is important to choose a qualified and experienced contractor to ensure the generator is built properly and will provide reliable power. With the right expertise, generator construction can be a rewarding and successful process that results in a reliable power source.

How are generators constructed?

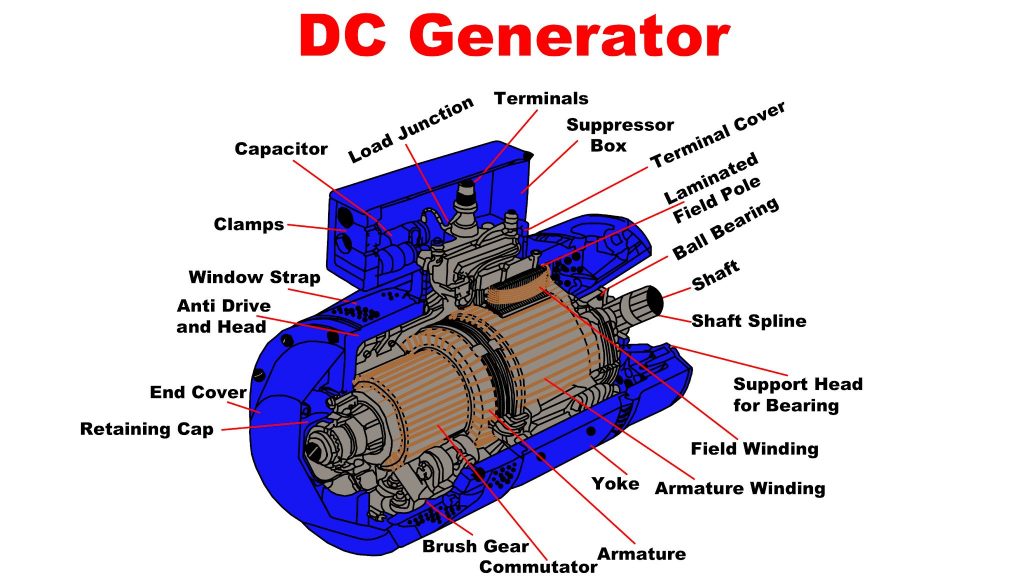

A generator is a device that uses mechanical energy to create electrical energy. The construction of a generator involves many different components, including an armature, field coil, commutator, brushes, and a frame. The armature is the rotating part of the generator and consists of copper coils that are wound on a core. The field coil is a stationary part of the generator and is composed of copper wire wound around an iron core. The commutator is the part of the generator that connects the armature to the field coil.

It consists of a series of copper segments that have been insulated from each other. The brushes are made of carbon and are used to maintain constant contact between the commutator and the field coil. The frame of the generator is usually made of steel and is used to hold the other components together. The frame also acts as a support when the generator is mounted in its operating environment. Lastly, the generator should be connected to a power source, such as a battery or a solar panel, in order to produce electrical energy. With the right components, a generator can be constructed in order to effectively produce electrical energy.

What are generators used for in construction?

Generators are a vital tool in construction projects. They provide a reliable source of power, enabling the efficient operation of construction equipment. The generators used in construction are usually larger than those seen in other applications, ranging in size from small portable units to huge industrial grade models. Generators can be used to power lights, tools, and machinery, providing the necessary energy to complete any construction project. These units can also be used to run compressors and pumps, as well as to provide power to welders, grinders, and other heavy-duty equipment.

In many cases, generators are used as a backup power source. If the main power source is interrupted, a generator can be used to keep the project running until power is restored. This ensures that construction is not delayed or interrupted due to a lack of energy. Generators can also be used for emergency lighting and to power emergency generators, allowing construction workers to operate safely in the event of a power outage. The generators used in construction must be well-maintained in order to ensure their reliability and safety. Regular maintenance checks should be carried out to ensure that the generator is running at optimal efficiency. This includes checking for fuel leaks and ensuring that the generator is connected correctly to the power source.

What size generator do I need for construction?

When it comes to generator construction, the size of the generator you need depends on the amount of power you require. If you need to power a few light tools and equipment, a small generator such as a 2,000-watt model should be sufficient. However, for more power-hungry items such as large power tools and heavy machinery, you will need a larger generator, such as one of 10,000 watts or more. When deciding on a size, it is important to calculate the total numbers of watts that the equipment you are powering requires, then add an additional 15 to 20 percent to accommodate for power surges. This will ensure your generator will be able to handle the load.

If you are going to operate the generator for more than 8 hours a day, you will need to look for models that have a high fuel economy. A larger generator may require more fuel, but it will also be able to power larger items and run for longer periods of time. Other considerations include the type of fuel you want to use, the noise level of the generator, and the availability of service and spare parts. Make sure to research the model you choose carefully and read reviews to get an idea of the performance of the potential generator. In conclusion, what size generator you need for construction depends on how much power you require and the type of tools and equipment you will be powering. It is important to consider all factors carefully before making your decision.

What will a 12000 watt generator run?

It can also power lights and other electrical appliances, making it an ideal choice for nighttime work and areas with limited access to power sources. On the construction site, the generator can provide a steady supply of electricity to power large pieces of machinery and tools. It can also be used to back up other power sources in case of an emergency. A 12000 watt generator would be able to provide enough power for a welding machine, a winch, and a sump pump. These machines can be used for many different purposes, including welding steel beams, lifting large objects, and draining excess water.

For contractors looking for a reliable source of power, a 12000 watt generator is an excellent choice. It is powerful, efficient, and can be used in a variety of construction scenarios. With proper maintenance and regular use, the generator can provide consistent energy for many years.

How thick should a concrete slab be for a generator?

Generally, a concrete slab should be at least four inches thick for a generator, although the exact thickness is determined by the size and weight of the generator itself. For example, if the generator is very large and heavy, the thickness of the slab should be increased to six inches or more. Regardless of the size of the generator, the concrete slab should be reinforced with steel mesh or rebar to provide added strength and durability. This will help to ensure the slab is able to withstand the vibration of the generator and any other external forces that may affect it. The mesh or rebar should be embedded into the slab at least two inches deep.

In addition to reinforcing the slab, it is also important to make sure that a vapor barrier is placed between the concrete and the ground. This will prevent moisture from seeping into the slab and causing damage or premature deterioration of the generator. Finally, the concrete slab should be designed to allow for drainage. If water or other fluids are able to collect around the generator, it could cause corrosion and other damage. The slab should be equipped with a drainage system that moves any liquid away from the generator and into a safe disposal area. Overall, it is important to ensure that the concrete slab for the generator is thick enough to support the generator’s weight and is reinforced with steel mesh or rebar for added strength. The slab should also include a vapor barrier and a drainage system to protect the generator from water damage and other external forces.

What is a generator in construction?

It can be used to power tools, lights and other electrical equipment that would otherwise require a permanent power source. Generators often come in a range of sizes and capacities, so they can be used to suit a variety of applications. Generators are often mounted on trailers so they can be moved easily and conveniently from location to location. This makes them ideal for construction sites which may require power in different places at different times. Generators are powered by a variety of fuel sources, depending on the model and the size of the generator.

The most common fuel sources for generators include diesel, gasoline and natural gas. When selecting a generator for construction, it’s important to consider the amount of power needed, the size of the area which needs to be powered and the type of fuel source being used. It’s also important to ensure the generator is properly maintained and serviced to avoid any potential problems. Generators are a vital piece of equipment for any construction site and can be used to provide power for a wide range of applications. By ensuring the correct generator is chosen for the job, construction sites can benefit from reliable power sources.

How much does a construction generator Cost?

A construction generator can be an expensive purchase, depending on what size and type you’re looking for. Prices can range from a few hundred dollars to thousands of dollars. You should also factor in the cost of fuel, regular maintenance or repairs, and other related expenses. The cost of a construction generator will usually depend on its power output. The higher the power output, the more expensive the generator will be.

It may also be more expensive to purchase a generator with a soundproof enclosure or a unit that runs on natural gas instead of gasoline. Size is also an important factor when it comes to construction generator costs. Portable generators are usually less expensive than larger, more powerful models. Larger models may require additional features such as double-walled fuel tanks, which can add to the cost as well. When purchasing a construction generator, it’s important to consider the usage and how much you’ll actually need the generator for. Some models are more expensive but offer more power and features, while others are less expensive but offer less power and features. Finally, it’s important to factor in the cost of installation when considering the cost of a construction generator. This cost can vary widely depending on the complexity of the installation, the type of generator, and the company you choose to install it. As with any major purchase, it’s important to shop around to get the best deal.

What size generator will run a whole house?

When it comes to generator construction, determining what size generator will run a whole house can be a tricky proposition. Generally, you need to consider the total wattage of the appliances in your home, as well as the total wattage of any additional items you might want to run. Depending on how many appliances you need to power and how much wattage they require, you may need a generator with a wattage rating in the 10,000 to 20,000 watt range. It is also important to note that a generator will not run at its maximum wattage all the time. Instead, it will automatically adjust the amount of power it provides based on the load you are requesting.

This means that you may need a higher wattage rating than you think in order to have enough power for everything. Another factor to consider is fuel type. You can choose from natural gas, propane, or diesel-powered generators. Natural gas and propane are typically more expensive than diesel, but they may be a smart choice if you plan to use the generator for a long-term project. Finally, consider the size of the generator itself. If you are considering a whole-house generator, it may need to be located outside of your home. A larger generator will be more powerful, but it may need to be installed in a spot that is adequately ventilated and away from flammable materials. In short, the size of generator you need to run a whole house depends on a variety of factors, such as the total wattage of your appliances and items, the fuel type you prefer, and the size and location of the generator. Consider all of these items when making your decision to ensure you have enough power for your needs.

How big of a generator do I need for a 2500 square foot house?

When it comes to constructing a generator for a 2500 square foot house, it’s important to consider the size of the generator you’ll need. A generator’s wattage should always exceed the wattage requirement of the appliances you plan to power. In general, a generator with a 5,000 to 7,500-watt capability should be able to power the average-sized house of this size. You’ll need to factor in the wattage of your largest appliance and the number of other appliances you’ll be powering with the generator in order to get an accurate estimate of the wattage you’ll need. It is also important to note that the larger the generator, the more fuel it will consume, so it’s important to strike a balance between the size of the generator and your budget.

If you plan on powering large appliances such as a refrigerator or air conditioner, then you will likely need a generator with even more wattage than 7,500. In this case, you’ll want to consider a generator in the 10,000-15,000 watt range. Finally, if you plan on powering your entire home, you will need to look into a heavy duty generator with a 20,000+ watt capability. These larger generators are more expensive, but they will be able to provide enough power for an entire house. Overall, deciding on the size of a generator for a 2500 square foot house requires careful consideration and research. The size of the generator you need depends on the wattage requirements of the appliances you plan to power and the size of your budget.

What kind of generator do they use on construction sites?

Construction sites often use generators to provide them with the necessary power for their projects. Generators used in construction sites are usually heavy-duty, reliable units that can handle the demands of operating in harsh, dirty environments. Commonly used generators on construction sites are diesel-powered, as they are more rugged and reliable than gasoline-powered generators. The diesel-powered generators also provide more power than their gasoline-powered counterparts, making them ideal for powering larger pieces of equipment. Additionally, these generators are known for their fuel efficiency, providing a cost-effective solution to powering construction sites. Finally, these units are also easy to maintain, which helps ensure they will remain reliable while working on the job site.

Are dual fuel construction site generators the best option?

Are dual fuel construction site generators the best option for powering up construction sites? It’s a great question that many construction site owners and managers are asking themselves. Dual fuel generators are an excellent choice because they offer a lot of flexibility in terms of fuel source. They can run on diesel, gasoline, or natural gas, so you can use the fuel source that best suits your needs. These generators are also incredibly powerful, providing up to 10,000 watts of power – more than enough to power all the tools and equipment needed on a construction site. They are also relatively quiet, making them less disruptive to the surrounding area.

The cost of dual fuel generators is also lower than other types of generators, so they are a great value for the money. They are also easy to maintain, so you can be sure that they will be up and running when you need them. Overall, dual fuel construction site generators are a great option for powering up your construction site. They offer a lot of flexibility, power, and cost effectiveness, making them the ideal choice for any construction project.

Is there a generator that starts with a push button?

It eliminates the need for manual starting, which can be difficult. A push-button start generator is designed to start up with the press of a button. The button can be located on the generator itself or located remotely. This makes it easier to start the generator without needing to be near it. Push-button start generators are found in many types of applications.

This includes home generators, industrial generators, and power plants. The push-button start feature makes these generators easier to operate and maintain. Push-button start generators are relatively simple to construct. They require a starter motor, a starter switch, and a battery. When the switch is pressed, the motor engages and the generator starts. Overall, push-button start generators are a great option when it comes to generator construction. They are easy to use and maintain, and can be found in many types of applications.

Why choose Caterpillar for your construction generator?

Their advanced engineering and design provide quality and reliability that is second to none. With Caterpillar’s generators, you can be sure your construction projects will be powered up and running with minimal downtime. Caterpillar’s generators feature a variety of power outputs, from small to large capacity models. This allows you to choose the best option for your particular application. Whether you need to power a single construction site or multiple projects at once, Caterpillar provides the perfect solution.

Caterpillar also offers outstanding customer service and product support. They have dedicated teams of experts who can assist you with any questions you may have or help troubleshoot any issues you may encounter. Caterpillar generators are easy to install and maintain, and they are built to last. With durable parts and long-lasting components, you can be sure your investment will provide reliable power for years to come. Finally, Caterpillar generators are affordable and energy efficient. Their energy saving technology will help you save money on fuel and power, while also helping the environment. So if you’re looking for the perfect generator for your construction needs, look no further than Caterpillar.

Can a generator power a house?

It can be used to power a whole house, depending on the size of the generator and the needs of the home. Generators come in a variety of sizes and can be used to provide emergency power during a power outage or as a primary power source in remote or off-grid locations. When considering a generator to power a house, it is important to be aware of the load requirements. The load must correspond to the capacity of the generator and must be properly sized for the home. The generator should be able to handle the total load of all the electric appliances and systems in the house.

When installing a generator, it is important to consider the fuel type and the type of generator. A diesel generator is often used to power a house due to its efficiency and strong power output. Other fuel sources may also be available, such as natural gas, propane, or solar. The generator must also be properly maintained and serviced in order to ensure that it is running efficiently. Regular maintenance and service will help to ensure that the generator is running safely and reliably. In conclusion, a generator is a great way to provide power to a house, but care must be taken to ensure that the generator is properly sized, the fuel source is appropriate, and the generator is serviced and maintained regularly. With the right setup, a generator can provide reliable and efficient power for a house.

What is the best house generator?

The best house generators are those that are reliable and efficient, with a long lifespan and excellent fuel economy. They should be able to provide steady power, with minimum disruption and a low risk of breakdown or malfunction. Additionally, they should be easy to install and maintain, and be able to work with a range of components. When looking for a house generator, you should consider the size of your project and the amount of power you will need. It is also important to look for a generator that is designed to meet relevant safety standards and comply with building regulations.

The best house generator for your project depends on your individual needs and budget. It is important to do your research and compare different models to make sure you are getting the best value for your money. For construction projects, it is essential to choose a generator that will be reliable, efficient and cost-effective. With proper research and a good quality generator, you can ensure that your project is completed to the highest standards.

How to build an enclosure for a portable generator?

It keeps your generator protected from outside elements, like dust, rain, and wind, as well as potential theft or damage. First, you’ll want to consider the size of your generator to ensure that the enclosure you build is large enough. You’ll also want to consider the material of the enclosure. Wood is a popular material, but you may also choose to use metal or something else. Next, you’ll want to measure and cut the material you’ve chosen.

Make sure that the pieces fit together properly and that you’ve added enough bolts, screws and hinges to ensure the enclosure is secure. Once the pieces are cut, it’s time to start putting the enclosure together. Begin by assembling the walls, making sure that the pieces fit and that the walls are straight. Once the walls are assembled, you can start attaching the roof and the floor. Finally, you’ll need to add a door to the enclosure. Make sure the door closes tightly and securely, and that it is easy to open and close. Once the door is installed, your enclosure is complete and your generator is ready to use.

What is a residential generator?

It is typically much smaller than industrial generators and runs on natural gas or propane. Residential generators come in a variety of sizes and styles. They can range from small portable models to larger stationary models. Their main purpose is to provide reliable power during extended power outages. A residential generator can often be used to power essential appliances, such as refrigerators, freezers, sump pumps, and other household systems.

It can also provide backup power for lights, TV, and other electronics. When selecting a residential generator, it is important to consider the size and type of generator needed for the project. The size of the generator will depend on the power requirements of the appliances and systems it needs to run. The type of generator will depend on the fuel source available and the desired energy efficiency. Finally, it is important to consider the cost of installation, maintenance, and repair of the residential generator. This will help ensure that the generator is properly installed and maintained for years to come.