Testing the output of a gas generator is an important process to ensure safe and efficient operation of the machine. Before testing, it is important to ensure that all safety protocols are observed. The output of the generator can be tested by checking the voltage and current output, as well as the frequency of the generated power. Additionally, the performance of the generator should be checked for the presence of any vibration, noise and leaks. A professional technician should be consulted to properly perform the generator testing.

They will use specialized equipment to accurately measure the output of the generator. The technician should also test the fuel system of the generator. This includes checking the fuel lines and connections, and verifying the fuel supply and pressure. Once all the tests are completed, the technician should provide a report outlining the performance of the generator. This will give the user an indication of its safety and efficiency, allowing them to make any necessary changes or repairs.

Why is my generator running but not producing power?

Testing generator output is essential to ensure a reliable power source. If the generator is running but not producing power, it could be due to a few different reasons. First, the generator may not be connected to a power source, so it won’t be able to produce power. The generator should be connected to a power source, either through a wall outlet or a power line, to be able to produce power. Second, the generator may not be properly wired.

If the wiring is not correct, the generator won’t be able to produce power. An experienced electrician should be able to check the wiring and make the necessary repairs. Third, the generator may not be getting enough fuel. The generator needs a steady supply of fuel to be able to produce power, so it’s important to ensure that it has enough fuel. Finally, the generator may be having issues with its internal components. If the generator’s internal parts are damaged or malfunctioning, it won’t be able to produce power. An experienced repair technician should be able to inspect the generator and make the necessary repairs. Testing generator output is crucial to ensure a reliable power source. If the generator is running but not producing power, it could be due to a variety of issues, and an experienced professional should be consulted to make the necessary repairs.

What should a generator output voltage be?

When testing a generator output, it is important to ensure that the output voltage is within acceptable limits. This can be done by measuring the voltage at the output of the generator. The output voltage should not exceed the rated voltage of the generator, otherwise the generator may overheat or suffer damage. The output voltage should be at least 5% higher than the rated voltage of the generator, so that it can account for any power losses during operation. This is especially important if the generator is being used to power sensitive electronic devices.

The output voltage should not be too low either, as this can lead to poor performance of the device being powered by the generator. A good rule of thumb is for the output voltage to be no lower than 95% of the rated voltage of the generator. It is also important to monitor the output voltage during operation, as fluctuations in the voltage can cause damage to the device being powered. Any significant deviation from the rated voltage should be investigated immediately. Overall, when testing a generator output, it is important to ensure that the output voltage is within the acceptable limits. The voltage should not exceed the rated voltage of the generator, and should be no lower than 95% of the rated voltage. Monitoring the output voltage during operation is also important, as any significant deviations from the rated voltage should be investigated immediately.

How do you load test a generator?

The generator is subjected to an increasing level of load, and its performance is monitored at each step. The load may involve powering an electrical device, such as a motor, or testing under a simulated load. The monitored performance data is used to determine the generator’s capacity, efficiency, voltage stability and other characteristics. Different tests can be performed to determine the effectiveness of the generator. Tests can be done to measure the capacity of the generator, its response time, and its ability to handle various loads.

Additionally, tests can be done to check the generator’s safety and reliability. The test results can then be used to make adjustments to the generator and to improve its performance. This is important for ensuring that the generator provides the necessary power for a given application. Load testing a generator is an essential step in testing generator output, and it can provide valuable information about the generator’s capacity, efficiency, and reliability. Once the tests are complete, the generator can be used with confidence that it will perform as desired.

What are the types of generator testing?

It helps to ensure that the generator is operating safely and efficiently. There are several types of generator testing that can be done. One type of testing is a load bank test. This test is used to measure the output of a generator under various load conditions. The load bank will be connected to the generator and the output will be tested to make sure the generator is producing the proper current and voltage.

Another type of testing is a power factor test. This test is used to measure the power factor of the generator. The power factor test will check to make sure the generator is producing the correct amount of power and that it is producing it in an efficient manner. An insulation test is also used to test generators. This test is used to make sure the insulation on the generator is in good condition. Insulation testing will check to make sure the insulation is not cracked or damaged and that it is providing adequate protection against electric shock. An efficiency test is also used to test the efficiency of the generator. This test will measure the amount of power the generator is producing compared to the amount of fuel it is consuming. This test will help to ensure that the generator is operating at its peak efficiency. Finally, a no-load test can be used to test the generator. This test will measure the current and voltage of the generator when it is not producing any power. This test can help to ensure that the generator is not producing too much power or too little power.

What are the test conducted on generator?

There are various tests that can be conducted to verify the functionality of the generator. The first test is to measure the voltage and frequency of the output. This can be done by connecting a multimeter to the generator and taking readings to compare with the rated output. The second test is to check the phase displacement for balanced three-phase systems. This requires connecting a wattmeter or phase angle voltmeter to measure the phase shift between the generator output and the reference phase.

The third test is to measure the power factor of the generator. This is done by connecting a power factor meter to the generator and measuring the ratio between the active and apparent power. The fourth test is to measure the efficiency of the generator. This is done by measuring the input and output power of the generator and calculating the efficiency. The fifth and final test is to measure the harmonic distortion of the output. This is done by connecting a harmonic distortion meter to the generator and measuring the relative amount of distortion present. These tests are important to ensure that the generator is working properly and that the output is in line with the required specifications.

What voltage should a generator put out?

It is important to know what voltage a generator should put out when testing its output. Generally, most generators put out between 120-240 volts of alternating current, or AC. If you are unsure of the output voltage, it is best to check the manufacturer’s manual for specific details. Before testing the generator output, be sure to allow the generator to run for at least 10 minutes so that it can reach stable power output. When using a multimeter to measure the output voltage, you should set it to the AC voltage range.

If the voltage is lower than expected, the generator may not be functioning properly or may need servicing. In this case, a qualified technician should assess the generator to determine the cause of the problem. It is also important to check the generator’s frequency during output testing. The frequency should be close to the nominal frequency specified by the manufacturer. Generally, the output voltage should remain constant, even if the load changes. The output of the generator should be checked regularly to ensure that it is operating correctly. Testing the generator output will help prevent breakdowns, reduce power losses, and ensure the generator is providing optimal performance.

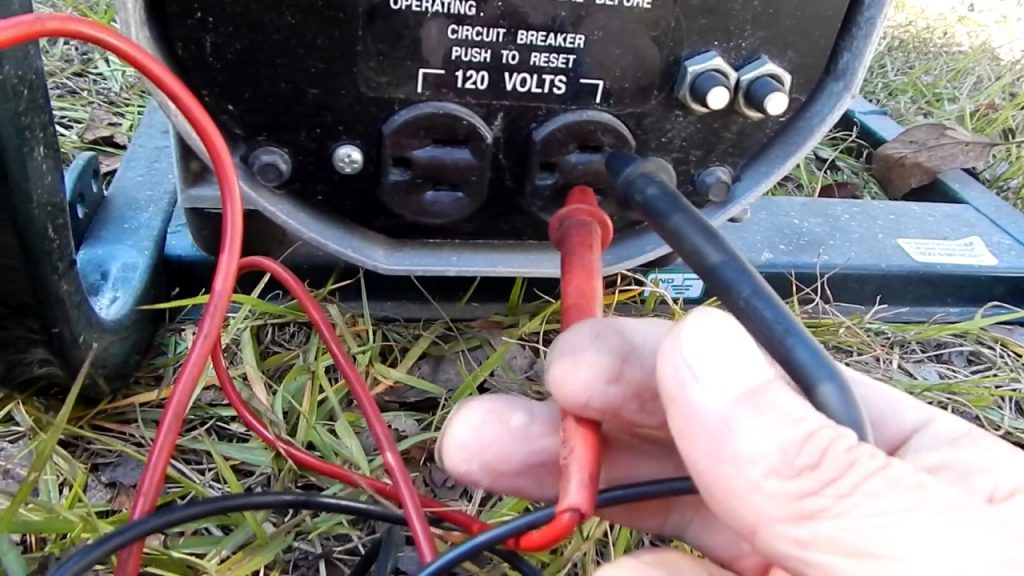

How do you check the voltage of a generator?

Testing the output of a generator requires you to check the voltage of the generator. To do this, you will need a multimeter or a voltmeter. Begin by turning off the generator and disconnect all other electrical systems connected to it. Make sure the generator is cooled down before starting. Connect the multimeter or voltmeter to the generator’s terminals and turn the generator back on. The voltage of the generator should be displayed on the multimeter or voltmeter. If the voltage is below the desired level, it is best to get the generator checked by a professional.

How can I tell how many watts my generator is putting out?

Testing generator output can be tricky, but the easiest way to determine how many watts your generator is putting out is with a wattmeter. With a wattmeter, you can accurately measure the output of your generator in watts. To use a wattmeter, you’ll need to attach the wattmeter’s input leads to the generator’s output terminals. Be sure to turn off the generator and disconnect it from any load before attaching the leads. Once you have the leads attached, turn the generator back on and take a reading from the wattmeter.

The number you see on the wattmeter is the wattage output of your generator. This is the maximum wattage the generator is capable of producing. It is important to note that the wattage can vary depending on the load that the generator is connected to. To ensure that the wattmeter is providing an accurate reading, you should repeat the test a few times. If the wattage output remains consistent, then you can rest assured that the wattmeter is providing an accurate reading of the generator’s output. With the help of a wattmeter, you can accurately measure the output of your generator in watts. This will help you determine whether your generator is capable of supplying the power needed for the job. It will also help you maintain the generator and keep it in optimal working condition.

How to test the output of a generator?

The first step is to compare the output of the generator with the input that is expected. Any discrepancies between the input and output should be noted and investigated. It is also important to test the quality of the output. This can be done by running the output through a consistency checker to make sure that it meets the desired standards. Any errors that are found should be addressed and corrected.

The next step is to test the efficiency of the generator. This involves running tests to measure the amount of time it takes the generator to generate the output. If the generator is taking too long, then adjustments may need to be made to increase its performance. Additionally, the generator should be tested for any potential security vulnerabilities. This could include tests to check for any potential backdoors that could be exploited by malicious actors. If any vulnerabilities are found, then measures should be taken to patch them immediately. Finally, it is important to perform long-term testing of the generator. This involves running the generator for an extended period of time and monitoring it for any potential problems. This will help ensure that the generator continues to perform as expected over the long term.

How to check generator output?

To check generator output, you will need some measurement equipment such as a multimeter. With the multimeter, you can measure the AC voltage and current output of the generator. Next, you should connect the output of the generator to a load and measure its output while running the generator. This will help you determine if the generator is operating at its rated capacity. Additionally, you can measure the frequency of the voltage and compare it to the rated frequency of the generator.

Finally, you should take readings of the output of the generator while the engine is running at different speeds. This will help you determine how the output of the generator changes as the engine speed changes. It is also important to check the generator’s control panel to make sure all the indicators are working as expected. This includes checking the voltage regulator, the oil pressure regulator, and the ammeter. In summary, checking generator output is a necessary step in ensuring that the generator is working properly. By using a multimeter and other measurement equipment, you can measure the generator’s output and compare it to the rated capacity. Additionally, you should check the control panel to make sure all indicators are working as expected.

How to test 12V generator?

The following steps can be used to test the output of a 12V generator:

- Start the generator to ensure that the engine is running properly.

- Connect a voltmeter to the output terminals of the generator and check the voltage reading. It should be 12V or close to 12V.

- If the voltage reading is not 12V, it is necessary to check for any loose connections or other errors.

- If all connections are secure, it may be necessary to adjust the generator’s settings to achieve the desired voltage.

- Once the voltage reading is 12V, it is important to measure the current output of the generator to make sure it is within the recommended range.

- Finally, it is important to inspect the generator for any signs of wear and tear, and to ensure it is in safe working condition.

How to test your generators voltage regulator?

To test the generator’s voltage regulator, you need to use a multimeter. Begin by connecting the multimeter to the generator’s battery terminals. Then, set the multimeter to the DC voltage setting. Start the generator and observe the voltage reading. The reading should be between 13.8 to 14.2 volts.

You can also test the voltage regulator by directly connecting the multimeter across the generator’s output terminals. With the engine running, the multimeter should read between 120 and 125 volts. If the voltage regulator fails to work properly, the multimeter readings will not be within the suggested range. In this case, it is best to replace the voltage regulator. Finally, it is important to make sure that the voltage regulator is of the correct type for your generator. Failing to use the correct type can lead to serious damage to the generator, so it’s important to double check before replacing the voltage regulator.

How to test diodes in your generator?

Diodes are an important part of a generator and should be tested regularly. To test diodes in your generator, you will need a digital multimeter. First, you must disconnect the generator from the power source. Then, consult the generator’s manual to locate the diodes and note the correct polarity. Using the multimeter, set it to the diode test mode.

Connect the positive lead of the multimeter to the positive side of the diode, and the negative lead to the negative side. A reading of between 0.4v and 0.7v indicates that the diode is working correctly. If the multimeter reads “OL” (overload) or 0v, the diode may be faulty and should be replaced. After testing all the diodes, reconnect the generator to the power source and run a test to make sure that the generator is functioning correctly. Finally, remember to always wear safety equipment when testing electrical appliances, such as gloves and safety glasses. This will help to ensure your safety and the safety of those around you.

How to test the Hertz in a generator?

Testing the output of a generator involves measuring the frequency of the output. The unit of measure most commonly used is Hertz (Hz). To test the Hertz in a generator, you will need a frequency counter or a tachometer. The frequency counter should be connected to the generator’s output terminals. When the frequency counter is activated, it will display the Hertz of the generator.

The reading should be within the generator’s rated frequency. To use a tachometer, the tachometer should be connected to the generator’s shaft. As the generator is running, the tachometer will measure the shaft speed and display the Hertz of the generator. The reading should be within the generator’s rated frequency. It is important to take multiple readings when testing the Hertz of a generator. This will ensure that the generator is running within the rated frequency for an extended period of time. If the generator is not running within the rated frequency, then it should be investigated further. Possible causes of this could include load imbalance, fuel quality, or a faulty part. Corrective action should be taken to resolve any issues found.